Cleaner Production Audit

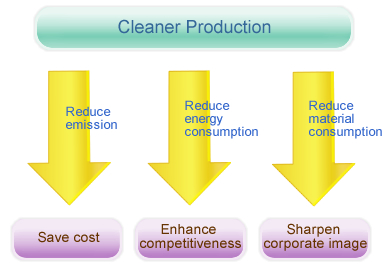

Our Cleaner Production audit methods and practices generate multiple benefits that are relevant to many of today’s most pressing global challenges, including:

- Mitigation of GHG emissions and adapting to climate change;

- Responding to increasing scarcity of water, fuels and other materials;

- Providing decent jobs; and

- Halting environmental degradation.

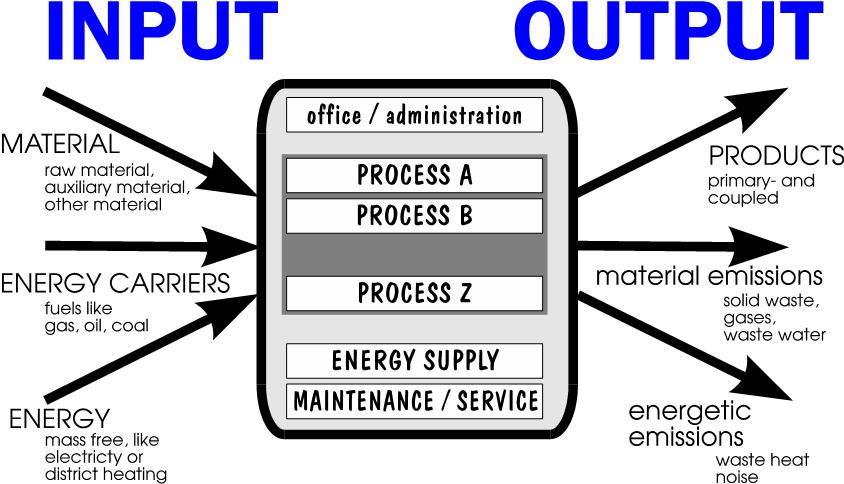

Our methodology is to analyzing the flow of materials and energy in a company, one tries to identify options to minimize waste and emissions out of industrial processes through source reduction strategies. Improvements of organization and technology help to reduce or suggest better choices in use of materials and energy, and to avoid waste, waste water generation, and gaseous emissions, and also waste heat and noise.

Following techniques we are using for getting best results.

- Good Housekeeping: appropriate provisions to prevent leaks and spills and to achieve proper, standardized operation and maintenance procedures and practices;

- Input Material Change: replacement of hazardous or non-renewable inputs by less hazardous or renewable materials or by materials with a longer service life-time;

- Better Process Control: modification of the working procedures, machine instructions and process record keeping for operating the processes at higher efficiency and lower rates of waste and emission generation;

- Equipment Modification: modification of the production equipment so as to run the processes at higher efficiency and lower rates of waste and emission generation;

- Technology Change: replacement of the technology, processing sequence and/or synthesis pathway in order to minimize the rates of waste and emission generation during production;

- On-Site Recovery/Reuse: reuse of the wasted materials in the same process or for another useful application within the company;

- Production of Useful By-Products: transformation of previously discarded wastes into materials that can be reused or recycled for another application outside the company; and

- Product Modification: modification of product characteristics in order to minimize the environmental impacts of the product during or after its use (disposal) or to minimize the environmental impacts of its production.